This website uses cookies

This website uses cookies to enable it to function properly and to analyse how the website is used. Please click 'Close' to accept and continue using the website.

June 2007 - The Horizon Building, Nottingham

Text by Elain Harwood, Images Courtesy Arup Associates

When the wind comes from the south, a sickly smell pervades Nottingham’s smart western suburbs. It is a reminder that cigarettes are still made here as well as consumed in their thousands on a Saturday night. John Player had begun manufacturing cigarettes in 1877, but in 1971 it moved to a new factory that was the state of the art in its construction, servicing and workers’ facilities. Slouched across the Nottingham flood plain, it is still remarkable today. In the manner of the times, the design project had a code name; unusually this stuck and the finished building became ‘Horizon’ – a reflection of its position on the city outskirts and also of its ‘blue sky’ thinking.

The 1960s saw the birth of the multi-disciplinary practice – architects, engineers, quantity surveyors and other specialists designing together from first principles, particularly for industry. The Building Design Partnership was quickly followed in 1963 by Ryder and Yates and by Arup Associates, founded by the engineers Ove Arup, Ronald Hobbs and Derek Sugden, and the architect Philip Dowson. Horizon took collective working methods a stage further, for the building contractors Bovis were an integral part of the design team from the first. Horizon was commissioned in 1968 and built in 1968-71.

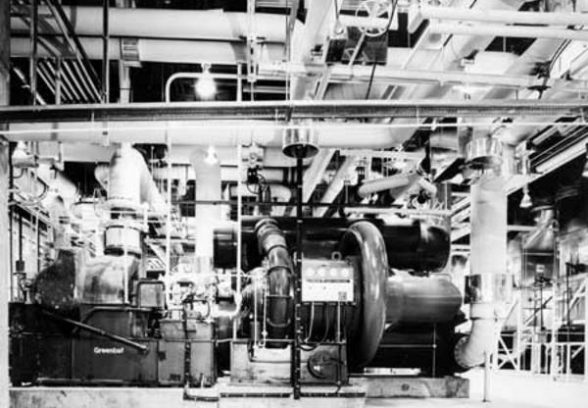

Horizon reflected changes in cigarette production towards faster handling and packaging. Services had to be exemplary, not only to keep the tobacco moist but to control every flake used in production: in June 1972 John Player’s tax bill was £1¼ million per day, calculated before manufacture – the dust from the floor and air filters was then weighed and tax recovered. The building is dominated by its efficient power house – the first in Europe run on North Sea Gas – and the refrigeration units alongside, one of the first and oldest surviving structures of GRP. More services are carried in a mezzanine floor, in the heavy roof structure and the supporting columns. So efficient are the services that the pungent smell that filters across Lenton is not found in the building. The irony was that such a carefully controlled environment should coincide with the realisation of the dangers of the product.

But what makes Horizon fearsome is its structure. This was the era of Norman Foster’s first lightweight sheds. By contrast Horizon is about as muscular as concrete can get, although, of course, its construction is fundamentally logical. Arup Associates had come to specialise in four-square units of columns that could be extended in any direction with their laboratories at Birmingham University. Here the structure of 36 near-identical units gives an enormous upper-floor space, its columns a hundred feet apart, over packing, storage and offices, while the massive pre-cast panels are facetted to give the shimmer of a rough diamond. At a late stage the canteen, bank and two shops were set in the same building as the manufacturing areas, and Horizon assumed its four-square, ‘packet of twenty’ appearance.

Horizon looks as good today as when it was built, and I love its massiveness and tactile griminess. It still has its panelled board room, while more space has been found in the mezzanine for offices. The production area looks even bigger as the rolling and packing machines have got smaller. The bank has gone, but otherwise the building has not changed – though the hundreds of ashtrays inside will have to go in July.

Elain Harwood is currently writing a Pevsner City Guide to Nottingham, as well as completing a book on post-1945 architecture.

Look for past Buildings of the Month by entering the name of an individual building or architect or browsing the drop down list.

Become a C20 member today and help save our modern design heritage.