This website uses cookies

This website uses cookies to enable it to function properly and to analyse how the website is used. Please click 'Close' to accept and continue using the website.

Image credit: Ken Kirkwood © RSHP Archive

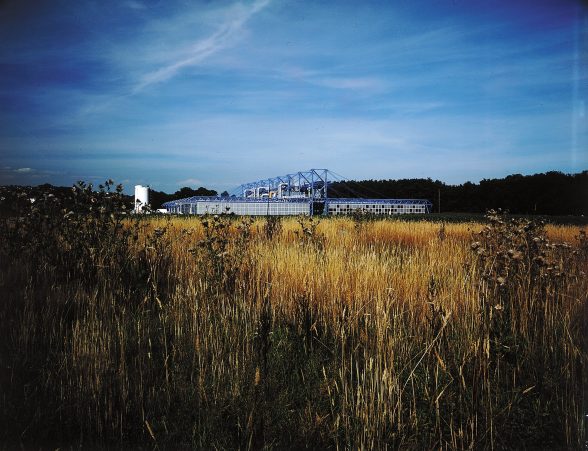

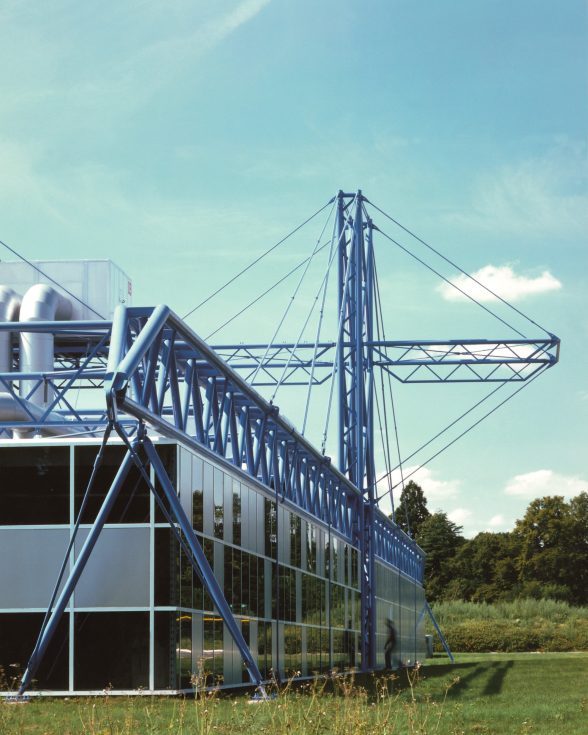

We’re thrilled to announce that the former Inmos Microprocessor Factory in Newport (1980-82) has been Grade II* listed, following an application by C20 Society submitted in 2021. Designed by Richard Rogers & Partners with structural engineering by Anthony Hunt, Inmos was the first microprocessor factory in the UK and the practice’s first major project to be completed in the UK following their breakthrough Pompidou Centre in Paris (with Renzo Piano, 1971-77). Like the Pomipdou, it is a prime example of High-Tech style structural expressionism with its critical services proudly displayed on the exterior of the building, while also recalling the drama of the nearby Newport Transporter Bridge (1906).

In 1982 Rogers said of his objective for the Inmos building: ‘The design should allow for maximum flexibility and potential growth and change in order to be able to meet the needs of a new and fast-evolving industry.’ Architecture critic Reyner Banham praised the factory as ‘the first really challenging building of the ‘80s’ and that walking along the service deck was ‘the most astonishing encounter with the sheer mechanics of modern architecture that one can experience’.

Image credit: Ken Kirkwood © RSHP Archive

The business of microprocessors

The silicon chip and the microprocessor were both invented in the post-war USA, which dominated their manufacture throughout the 1970s. As their military and civilian uses multiplied the governments of Japan, West Germany and then Britain sought to sponsor the establishment of domestic sources of silicon chips.

Inmos Ltd. was set up in 1978 as a publicly owned chip maker through the National Enterprise Board (NEB). The company’s name was an abbreviation for International Metal Oxide Semiconductor, and it was to operate in both the UK and the USA to encourage technology transfer. At its head were two Americans, Richard Petritz and Paul Schroeder, and one Briton, Iann Barron. The fledgling company established design offices in Bristol, England, and its first factory in Colorado Springs, USA and commissioned Richard Rogers to design its UK factory.

The design, led by project architect Mike Davies, was originally intended for a hilltop location in Bristol, the first choice of Inmos Ltd. However, the NEB as the owner came under political pressure to build the factory in an area with higher unemployment. When the incoming Thatcher government considered scrapping the whole project the Secretary of State for Wales, Nicholas Edwards, was able to make placing the factory in Newport a condition of the further funding needed to build it, awarded through the British Technology Group. The Prince of Wales officially opened the building on 25 February 1983.

Inmos was privatized through its sale to Thorn EMI in 1984 and in 1989 was sold on to the Italian and French conglomerate SGS-Thomson. In 2021 Nexperia, a company partly owned by the Chinese government, bought the factory but in 2022 was ordered to sell it under the National Security and Investment Act 2021, leading to its acquisition by current owners US-headquartered Vishay Intertechnology Inc in March 2024. Four decades on, the Newport plant remains the UK’s largest manufacturer of semiconductors.

Image credit: Ken Kirkwood © RSHP Archive

Design brief

The Inmos scheme began as a design for a model microchip factory, which could be built quickly (operational within a year of start on-site) in a wide variety of locations, and could be expanded or otherwise adapted without disruption to production. The technical brief demanded highly controlled clinical conditions (protected from dust and vibration) for the manufacture of microprocessors, as well as conventional office space and a staff canteen.

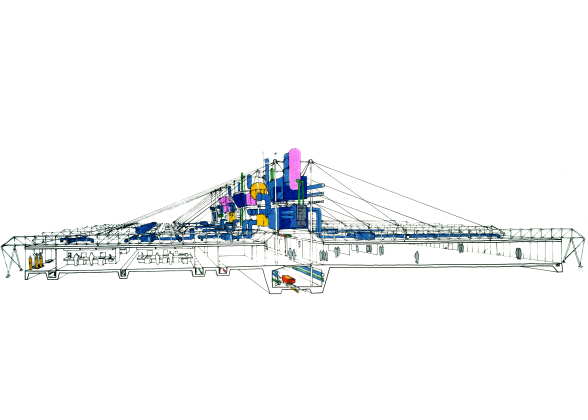

The practical purpose of the elaborate roof structure is to maximise the amount of open internal space uninterrupted by columns or load bearing walls. The exoskeleton of blue tubular steel masts provides support to services and to the two wings, allowing for column-free and extendable space. To either side of the line of spine towers is a covered area roughly 106 by 36 metres with a central ‘street’. This ‘street’ is the heart of the scheme, linking the ‘clean’ (microchip production) and the ‘dirty’ (office and support) wings of the building.

Off-site fabrication allows for quick assembly, with a flexible system that allows for the use of solid, opaque or transparent panels in cladding. The curtain walls of the building envelope are an aluminium grid holding removable thin square panels. Originally these were uniformly silver grey on the west production side, with a chequerboard of silver and glazing on the east offices side. Service boxes containing air-filtering equipment are placed along the spine between the towers. It was intended that these could be easily lifted off by crane for upgrading and none of the original 1982 boxes now remain. Similarly, the pipework visible sprawling over the flat roof has been continuously altered, although the general colour scheme of silver grey for air services, yellow for acidic gas and blue for structural elements has persisted.

Image credit: Ken Kirkwood © RSHP Archive

The most important example of High-Tech architecture in Wales, Cadw’s list description defines the significance of the building as follows:

• Design for flexibility – The suspended ceiling provides large interior spaces either side of the spine, free from any columns or load bearing walls, while the removable service boxes between the spine towers and exposed pipework on the roof allow for regular upgrading and reorganisation. The square grid walls also allow for removal and replacement of individual panels as the production within evolves.

• Expressed construction and services – The primary structural elements of the Inmos factory are its latticework towers, suspension rods and trusses and most of these are displayed as an exoskeleton. Services are also proudly expressed in the open roofscape. Although these services must change periodically the building’s aesthetic merit is preserved by maintaining a colour scheme of blue for superstructure, silver for air purification and industry standard yellow for acidic gas.

• Technological innovation and lightweight construction – The building used novel materials, technology and design solutions to enhance the prestige of the advanced manufacturing within. An innovative suspended ceiling delivers both the flexible interior and a framework on which to mount services. The factory is principally constructed from a highly complex latticework of tubular steel, a result of close collaboration between Rogers and Hunt as architect and engineer. The walls and ceilings are also thin and lightweight.

Image credit: Ken Kirkwood © RSHP Archive

John McElgunn, Senior Director, RSHP commented:

“The Grade II* listing of the Inmos Microprocessing Factory recognises how inventive industrial architecture can be when clarity, flexibility and technical intelligence come together. Inmos was never just a factory — it was a prototype for buildings that could be assembled rapidly, adapt to new technologies, and still carry the precision and lightness of great architecture. We hope the listing will allow the building to remain flexible to its evolving needs, and reaffirming our belief that highly technical environments need not sacrifice elegance or human clarity.”

Catherine Croft, Director of Twentieth Century Society commented:

“Inmos is one of the most important High-Tech buildings in Britain and so we’re delighted to see it recognised with Grade II* listing. The practice’s first major project to be completed in the UK following their breakthrough Pompidou Centre in Paris, it shares the same structural expressionism with its critical services proudly displayed on the exterior of the building. Impressively, it’s still serving the same purpose for which it was originally built after more than 40 years – testament to the ingenuity and excellence that remains at the heart of RSHP’s work.”

Image credit: Ken Kirkwood © RSHP Archive

Become a C20 member today and help save our modern design heritage.